ISO accreditation awarded to Alltech’s European mycotoxin laboratory

[DUNBOYNE, Ireland] – The Alltech 37+® mycotoxin analytical services laboratory in Dunboyne, County Meath, Ireland, was accredited in accordance with the international standard ISO/IEC 17025:2005 from Perry Johnson Laboratory Accreditation, Inc. This objective, third-party assessment distinguishes the managerial and technical requirements of the lab and ensures the accuracy and impartiality of analytical results.

The European Alltech 37+ mycotoxin laboratory, which opened in April 2016, is the third of its kind for Alltech, which has two similar laboratories in the U.S. and China. The proprietary 37+ LC/MS/MS analytical method, developed by Alltech, is included in the scope of accreditation. This analytical method is state-of-the-art in its detection and quantisation of more than 37 mycotoxins at parts per billion (ppb) and parts per trillion (ppt) levels.

“This accreditation sets the bar in global mycotoxin investigation and reaffirms our customers’ confidence in the precise, accurate and thorough testing of the Alltech 37+ mycotoxin analysis programme,” said Steve Mobley, manager of the European Alltech 37+ mycotoxin laboratory.

“Our diagnostic approach allows us to further investigate livestock and poultry health issues, study global mycotoxin trends and develop comprehensive, customised mycotoxin management programmes for our customers,” continued Mobley.

Led by Dr. Emma Daniels, senior analytical chemist and laboratory coordinator, the Alltech European 37+ laboratory provides much-needed, high-throughput mycotoxin profiling services to accelerate the detection process while saving time and money for European farmers and food producers.

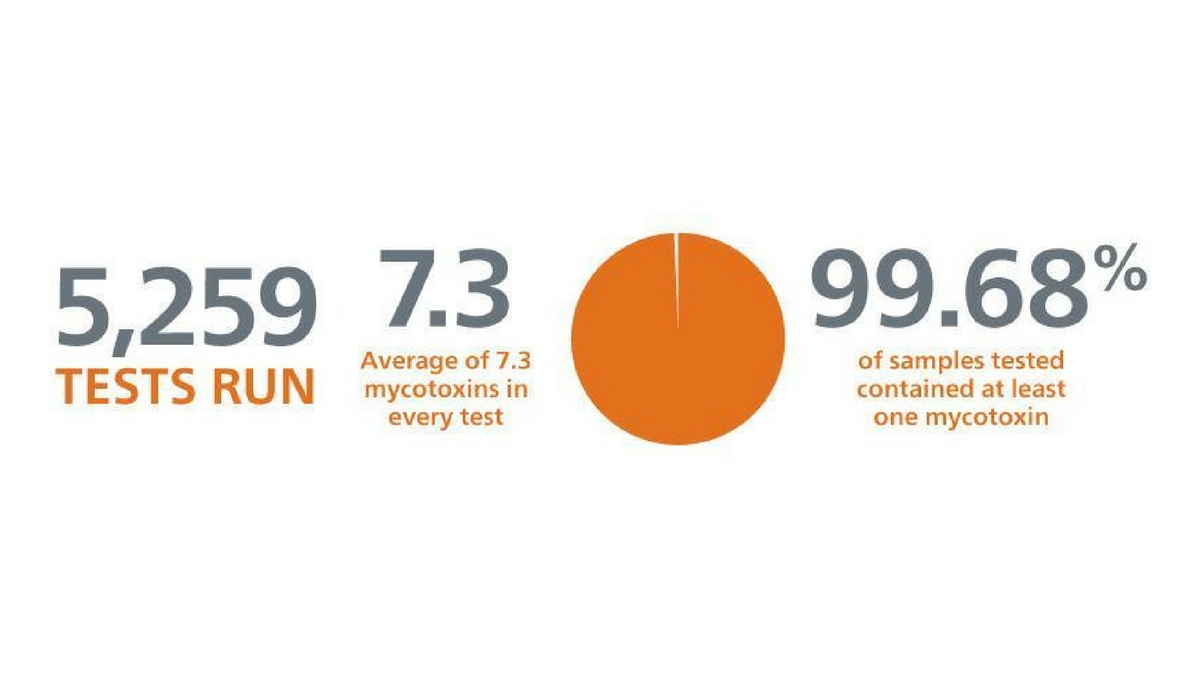

Run in conjunction with the Alltech® Mycotoxin Management programme, Alltech continues to collate a powerful database, which recognises mycotoxin issues throughout the world. To date, Alltech’s mycotoxin laboratories have analysed more than 14,000 samples since opening its first dedicated facility in Lexington, Kentucky, USA, in 2012.

Research carried out on mycotoxin samples analysed in January and February in North American silages showed evidence of type B trichothecenes and fusaric acid. Although type B trichothecenes are still a prevalent mycotoxin group found in silages that can damage the health and productivity of animals, recently, there has been increase in the number of cases of type A trichothecenes and other Penicillium mycotoxins. In Europe, type B trichothecenes are still common among silages, but there is also a high risk from the other Penicillium mycotoxins, which occurred in 45 percent of samples at an average of 1,533 ppb.

For further information on the Alltech Mycotoxin Management programme, please visit www.knowmycotoxins.com.

- Read more about ISO accreditation awarded to Alltech’s European mycotoxin laboratory

- Log in to post comments

<p>The Alltech 37+® mycotoxin analytical services laboratory in Dunboyne, County Meath, Ireland, has been accredited in accordance with the international standard ISO/IEC 17025:2005 from Perry Johnson Laboratory Accreditation, Inc. The European laboratory provides much-needed, high-throughput mycotoxin profiling services to accelerate the detection process while saving time and money for European farmers and food producers.</p>