Locations

We are proud to serve customers in more than 120 countries. Learn about our offices and how you can get in touch.

North America

Europe

Latin America

Asia Pacific

Africa

Middle East

We are proud to serve customers in more than 120 countries. Learn about our offices and how you can get in touch.

The Alltech® Feed Efficiency program supports your animals in achieving optimal health throughout their life cycle, addressing nutritional issues such as digestibility, diet flexibility, feed costs and overall performance.

With feed costs often accounting for up to 70 percent of production costs, it is important to make sure each bite of feed is digested efficiently.

The Alltech Feed Efficiency program utilizes technologies that work in synergy with the animal’s own digestive system to provide additional protein, amino acids and minerals for digestion. Supporting the animal's digestive system can help maximize nutrient release, achieve consistent performance and reduce the overall costs of feed.

Your livestock depend on you. Performance depends on the right mineral.

Do it right with the Alltech® Mineral Management program for better absorption, less waste and optimum health.

Mineral management is more than just preventing deficiencies.

Incorrect mineral supplementation can have major consequences on animal health and productivity. Traditional methods of supplementation have used inorganic minerals. However, inorganic minerals are poorly absorbed by the animal. This has caused a shift to organic mineral supplementation in many markets.

Break with tradition and feed your animals the modern way.

Alltech has proven that organic trace minerals in the form of Bioplex® and Sel-Plex® can be included at significantly lower levels while improving animal performance. This optimizes animal mineral requirements and reduces negative environmental impacts. We call this innovation Alltech’s Total Replacement Technology™ (TRT).

The Alltech Mineral Management program guarantees organic minerals that are better absorbed, stored and utilized by the animal. This meets the higher nutrient needs of modern livestock for growth, reproductive performance and animal health.

Learn more about 7MB VET BOLUS™ here.

At Alltech, we realize that raising high quality, efficient and healthy animals is far more than a simple task, which is why our support goes beyond nutrition.

The Alltech® On-farm Support program partners with producers around the world to help them reach their goals, troubleshoot issues and lay a foundation for a profitable and sustainable future. Bringing together almost four decades of research and field-proven products with a team of committed experts, the Alltech On-farm Support program can help you increase your efficiency, productivity and profitability.

Through our innovative study of nutrigenomics, our nutritional technologies help animals maximize the nutrients in their feed for optimal well-being and performance.

We work with producers across the globe to address the issues most important to them, including feed efficiency, antibiotic-free production, food enrichment and the management of mycotoxins, gut health, protein, enzymes and minerals.

Our gut health technologies, for example, are backed by extensive research, including more than 730 trials. As antibiotic regulations tighten globally, we are positioned to provide field-proven solutions for the intestinal integrity and overall well-being of animals.

Ask your feed provider how you can take advantage of Alltech technologies in your operation.

Finding experienced workers continues to be a challenge for farmers across the world. The Alltech On-farm Support program can provide customized, bilingual workshops for your team, helping you ensure that all employees are following the same protocols and routines, and understand the reasons behind them.

The Alltech® Gut Health Management program is essential to building a foundation for lifelong animal performance and producer profitability.

Our gut health technologies are backed by extensive research, including more than 730 trials. As antibiotic regulations tighten globally, we are positioned to provide field-proven solutions for the intestinal integrity and overall well-being of animals.

The Alltech Gut Health Management program focuses on:

The Alltech®In Vitro Fermentation Model (IFM) is a support tool for nutritionists to evaluate and troubleshoot rations in order to maximize feed efficiency and reduce ever-rising feed costs.

Nutritionists rely on nutritional models and chemical feed characteristics to formulate diets. However, this information is static and does not provide a complete evaluation of nutrient availability. Alltech IFM is a dynamic diagnostic tool that measures the digestion of feed in the rumen in real time. This allows us to get a comprehensive view of feed digestion as opposed to a snapshot from a single point in time.

Alltech IFM simulates rumen fermentation to evaluate the energy and protein availability of feeds. This technique is based on measuring gas production from microbial digestion as a proxy for real-time digestion. Since we continuously measure gas production, we are able to separate the energy contribution of feed ingredients by the rate of digestion. We can describe how much and at what rate carbohydrates from quickly degrading sources (e.g., starches and sugars) and slowly degrading sources (e.g., fiber) are contributing to the balance of the ration. We also measure microbial biomass to indicate protein availability and protein-to-energy balance in the ration. Alltech IFM analysis also includes a basic wet chemistry to provide a complete picture of the feed sample.

Feed samples are incubated using rumen fluid and a buffer system to mimic natural rumen fermentation in the animal. As digestion progresses, volumes of fermentation gases, such as methane and carbon dioxide, are continuously monitored using an automated system.

| Predicting the nutritive value of dairy cattle rations | Why use Alltech IFM | What is the Yea-Sacc Value Test? |

Ever-present in the farm environment and a potential threat to the productivity of even the best-run livestock production operations, mycotoxin contamination should be on every feed producer and farmer’s radar.

Alltech has developed a global solution to help control mycotoxins through a combination of mycotoxin management programs and technologies. Effective mycotoxin management is about seeing the whole challenge, from the farm to the feed mill and from risk assessment to feed management. The Alltech® Mycotoxin Management program provides a number of solutions to help you mitigate the threat you could face from field or storage mycotoxins.

For more information on our program and products, visit www.knowmycotoxins.com.

Contact us for more information

The Alltech® Protein Management program provides a source of consistent, high-quality protein for your animals, getting them off to the right start and keeping production on track to optimize performance.

Adding Alltech’s protein solutions to your feed can:

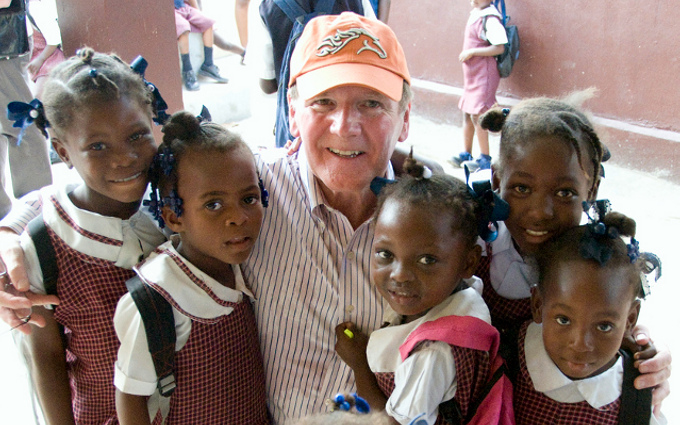

Alltech was founded in 1980 by Dr. Pearse Lyons with $10,000 and a dream. Today, Alltech remains a privately held company with a strong sense of commitment to the communities in which it operates.

Alltech believes in giving back. For this reason, we established the Pearse Lyons ACE Foundation, a charitable foundation to help fund the philanthropic efforts of our company, employees and partners around the world.

Merci de visiter notre site. Nous respectons votre vie privée et nous nous engageons à protéger les données personnelles que vous partagez avec nous sur ce site. Cette politique de confidentialité vous informe sur la manière dont nous traitons vos données personnelles lorsque vous visitez notre site Web (quelle que soit votre origine) et vous donne des informations importantes sur vos droits à la confidentialité.

Cette politique de confidentialité explique comment nous protégeons et utilisons les données personnelles que nous collectons sur ce site. Les informations incluses dans cette politique sont conçues pour expliquer pourquoi nous recueillons vos données personnelles, comment nous y accédons et les utilisons, et comment nous les stockons pour assurer leur sécurité. Veuillez lire cette politique de confidentialité avant d'utiliser le site Web ou de soumettre des données personnelles.

Qui est Alltech et pourquoi Alltech a-t-il publié une politique de confidentialité?

Fondée en 1980 par le Dr Pearse Lyons, entrepreneur et scientifique irlandais, Alltech découvre et propose des solutions pour la nutrition durable des plantes, des animaux et des humains.

Avec une expertise dans la fermentation de levure, la fermentation à l'état solide et la science de la nutrigénomique. Alltech est un producteur et transformateur de premier plan d'additifs pour levure, d'oligoéléments organiques, d'ingrédients, de prémélanges et d'aliments pour animaux.

Alltech, Inc a son siège social mondial situé au 3031 Catnip Hill Road, Nicholasville, Kentucky 40356, États-Unis, ainsi qu’un siège européen situé au centre All-Technology (Ireland) Alltech Bioscience Center, Summerhill Road, Sarney, Dunboyne. Alltech collecte et stocke les données personnelles que vous partagez sur ce site.

Alltech peut partager vos données personnelles en interne avec d'autres membres du groupe Alltech et avec ses fournisseurs de services qui aident Alltech à vous fournir des services spécifiques.

Alltech Inc («la société ») est composée de différentes entités juridiques, qui font toutes partie d’un groupe plus large : « le groupe Alltech ». Cette politique de confidentialité est écrite au nom du groupe Alltech. Lorsque nous mentionnons "Alltech", "nous", "notre" dans cette politique de confidentialité, nous désignons l'entreprise pertinente du groupe Alltech responsable du traitement de vos données. Cette politique de confidentialité s'applique à tous les sites Web et sociétés Alltech qui renvoient à ou font référence à cette politique de confidentialité.

Est-il possible d'obtenir des informations supplémentaires sur les politiques de confidentialité relatives aux autres sites Web Alltech ?

Si vous souhaitez consulter des informations supplémentaires sur nos politiques de confidentialité en relation avec d'autres sites Web Alltech ou déclarations de confidentialité affiliées, veuillez cliquer sur les liens de la politique de confidentialité des sites Web respectifs pour ces avis ou déclarations affiliées.

Alltech doit-il collecter des données personnelles conformément à la loi ?

Nous vous demanderons votre consentement avant de collecter vos données personnelles à des fins spécifiques. En général, nous collectons des données uniquement à des fins d'analyse de site Web. Nous n'utilisons pas d'adresses IP pour identifier des utilisateurs individuels. Lorsque nous sommes tenus de collecter des données à caractère personnel conformément à la loi ou à la réglementation afin d'exécuter un service spécifique ou de vous fournir un produit spécifique, nous avons besoin de votre consentement avant de pouvoir exécuter le service concerné ou de vous fournir le produit que vous avez contracté avec nous. Lorsque nous concluons un contrat avec vous, vous pouvez vous attendre à ce que notre contrat avec vous comprenne des informations sur la manière dont nous protégeons votre vie privée.

Alltech applique-t-il des règles de confidentialité et de protection des données telles que la RGPD ?

Alltech déploie tous les efforts raisonnables pour traiter les données conformément à la législation des pays dans lesquels nous opérons, y compris au règlement général de l’Union européenne sur la protection des données. (RGPD) Nous prenons les mesures appropriées pour protéger les données personnelles que vous communiquez à Alltech. Les données personnelles incluent toute information concernant une personne physique ou une personne concernée identifiée ou identifiable

Que se passe-t-il si Alltech change la façon dont il protège mes données personnelles ?

Si nous modifions nos pratiques pour améliorer encore la protection de vos données personnelles, nous mettrons à jour cette politique et publierons la mise à jour sur ce site Web. Dans certaines situations, nous pouvons également vous envoyer la politique mise à jour par courrier électronique. Veuillez consulter la politique de confidentialité à chaque fois que vous visitez le site Web d’Alltech afin de vous assurer que vous comprenez comment les données personnelles que vous fournissez seront utilisées.

Quels droits sur les personnes concernées s'appliquent aux utilisateurs des sites Web Alltech ?

Les utilisateurs des sites Web Alltech ont le droit d’accéder à leurs données, qu’Alltech les corrige, le droit de les transférer et le droit de les faire supprimer par Alltech à tout moment.

Les utilisateurs ont également le droit et la possibilité de gérer leurs abonnements Alltech à tout moment. Les utilisateurs des sites Web Alltech ont le droit de :

Demander l'accès aux données personnelles (communément appelées "demande d'accès aux personnes concernées") qu'Alltech possède sur vous.

Demander la correction des données personnelles que nous détenons sur vous. Ce droit vous permet de demander à Alltech de corriger les données incomplètes ou inexactes que Alltech détient à votre sujet.

Demander l'effacement des données personnelles que nous détenons à votre sujet. Ce droit vous permet de nous demander de supprimer ou de supprimer des données personnelles lorsqu'il n'existe aucune raison valable de continuer à les traiter. Notez cependant que nous ne pourrons peut-être pas toujours donner suite à votre demande d’effacement pour des raisons juridiques spécifiques que nous vous expliquerons, le cas échéant, au moment de votre demande.

Opposez-vous au traitement de vos données personnelles lorsque nous nous appuyons sur un intérêt légitime (ou sur l'intérêt légitime d'un tiers) et que quelque chose dans votre situation particulière vous donne envie de vous opposer à un traitement pour ce motif si vous estimez que cela a un impact sur vos droits et libertés fondamentaux.

Demander un transfert de vos données personnelles à un tiers.

Retirez votre consentement à tout moment lorsque nous comptons sur votre consentement pour traiter vos données personnelles. Toutefois, cela n’affectera pas la licéité des traitements effectués avant le retrait de votre consentement. Si vous retirez votre consentement, il se peut que nous ne puissions pas vous fournir certains produits ou services. Nous vous informerons si tel est le cas au moment où vous retirez votre consentement.

Comment recueillons-nous vos données ?

des données sur vous et sur vous, notamment par :

Interactions directes. Vous pouvez nous donner votre [Identité et Contact] en remplissant des formulaires ou en nous contactant par courrier, téléphone, courrier électronique ou autre. Cela inclut les données personnelles que vous fournissez lorsque vous :

• Vous renseigner sur nos produits ou services ;

• Créer un compte sur notre site web ;

• Abonnez à notre service ou à nos publications ;

• Demander que du matériel de marketing vous soit envoyé ;

• Participer à un concours, à une promotion ou à une enquête ;

• Donnez vos commentaires ou contactez-nous.

Technologies ou interactions automatisées.

Lorsque vous interagissez avec notre site Web, nous collectons automatiquement des données techniques sur votre équipement, vos actions de navigation et vos habitudes. Nous collectons ces données personnelles à l'aide de cookies, que nous expliquons plus en détail dans notre politique en matière de cookies.

Dans quel but collectons-nous vos données ?

Les données personnelles que vous partagez avec nous nous permettent de répondre à vos questions et / ou de vous livrer des courriels de marketing et newsletters électroniques auxquels vous êtes abonné. Il nous fournit également les informations dont nous avons besoin pour vous contacter en accord avec le consentement que vous nous donnez lorsque vos données personnelles sont collectées. Nous n'utilisons pas vos données personnelles pour la prise de décision automatisée ou le profilage.

Alltech utilisera vos données personnelles uniquement à des fins compatibles avec la raison initiale pour laquelle nous avons collecté vos données personnelles. Si vous souhaitez des explications sur la relation entre le traitement que nous effectuons et le but initial pour lequel vos données personnelles ont été collectées, veuillez nous contacter.

Si nous devons utiliser vos données personnelles à des fins non liées, nous vous en informerons et nous solliciterons votre consentement supplémentaire ou nous vous expliquerons pourquoi nous sommes légalement tenus d'utiliser vos données personnelles dans une situation donnée.

Veuillez noter que nous pouvons traiter vos données personnelles à votre insu et sans votre consentement, conformément aux règles ci-dessus, lorsque cela est requis ou autorisé par la loi.

Certains exemples de données personnelles que nous collectons sont regroupés comme suit :

• Les données d'identité comprennent [prénom, nom de jeune fille, nom de famille, nom d'utilisateur ou identificateur similaire et titre].

• Les données de contact comprennent [adresse de facturation, adresse de livraison, adresse électronique et numéros de téléphone].

• Les données de transaction incluent [les détails sur les paiements vers et depuis vous et d'autres détails sur les produits et services que vous avez achetés chez nous].

• Les données techniques incluent l'adresse IP, vos données de connexion, le type et la version du navigateur, le réglage et l'emplacement du fuseau horaire, les types et les versions de plug-in du navigateur, le système d'exploitation et la plate-forme, ainsi que d'autres technologies sur les périphériques utilisés pour l'accès de ce site].

• Les données de profil incluent [votre nom d'utilisateur et votre mot de passe, vos achats ou commandes, vos centres d'intérêt, vos préférences, vos commentaires et les réponses à des enquêtes].

• Les données d'utilisation comprennent [des informations sur la manière dont vous utilisez notre site Web, nos produits et services].

• Les données de marketing et de communication incluent [vos préférences pour recevoir du marketing de nous et de nos tiers et vos préférences de communication].

Nous ne collectons aucune catégorie particulière de données personnelles vous concernant (cela inclut des détails sur votre race ou votre ethnie, vos croyances religieuses ou philosophiques, votre vie sexuelle, votre orientation sexuelle, vos opinions politiques, votre appartenance à un syndicat, des informations sur votre santé, ainsi que vos données génétiques et biométriques.). Nous ne recueillons aucune information sur les condamnations pénales et les infractions.

Ce site Web peut-il être consulté sans partager de données personnelles ?

Vous pouvez accéder à de nombreuses pages de notre site Web sans nous communiquer vos données personnelles. Lorsque vous avez la possibilité de fournir des données personnelles via le site Web, par exemple en fournissant votre adresse électronique ou votre adresse personnelle, en soumettant vos informations personnelles, vous consentez à notre utilisation des données telles que décrites dans la présente politique de confidentialité et dans les déclarations de confidentialité qui apparaissent sur les formulaires par lesquels vous soumettez vos données personnelles.

Où Alltech traite-t-il les données personnelles ?

Alltech est le responsable du traitement des données personnelles que nous collectons. Alltech utilise parfois un fournisseur de services de traitement de données (processeur de données) pour traiter vos données personnelles. Lorsque Alltech utilise un service de traitement de données, le sous-traitant est tenu par contrat de mettre en place les mesures appropriées pour protéger les données personnelles. Le responsable du traitement des données traite les données uniquement dans le cadre des instructions d’Alltech et conformément aux lois de l’Union européenne. Il est possible que vos données personnelles soient stockées en dehors de l'Union européenne, notamment aux États-Unis. Les responsables de traitement de données travaillant avec Alltech sont contractuellement tenus de protéger leurs données à caractère personnel conformément au droit de l'Union européenne, quel que soit leur emplacement.

Combien de temps conservons-nous vos données personnelles ?

Alltech conserve les données personnelles que vous soumettez afin de répondre à vos questions et / ou de livrer les courriels de marketing et les newsletters électroniques auxquels vous êtes abonné. Si vous demandez la fin de votre abonnement, Alltech conservera les données personnelles soumises pendant un an pour la préparation des statistiques et le traitement de vos commentaires et de vos questions. Nous utiliserons cette approche de rétention à moins que vous ne nous disiez que vous ne souhaitez pas que Alltech conserve ces informations pendant cette période. Alltech supprimera vos informations à votre demande. Alltech peut également être tenu de partager des données à caractère personnel avec les autorités judiciaires, mais ne le fera que si cela est légalement requis.

Que dois-je faire si je ne veux plus recevoir de messages marketing d'Alltech ?

Vous pouvez nous demander de cesser de vous envoyer des messages marketing à tout moment en suivant les liens de désabonnement inclus dans les messages marketing qui vous sont envoyés ou en nous contactant à tout moment à privacy@Alltech.com.

Lorsque vous refusez de recevoir des messages marketing, nous honorerons votre demande en ne vous envoyant plus de messages marketing. Nous utiliserons toujours vos données personnelles si nous les avons résultant d'un achat de produit / service, de l'enregistrement de la garantie, de l'expérience du produit / service ou de toute autre transaction. Nous conservons vos informations personnelles dans des situations similaires à celles décrites, afin de pouvoir continuer à vous fournir des services relatifs à ces transactions.

Comment puis-je contacter l’équipe de confidentialité des données d’Alltech pour poser des questions ou obtenir des informations sur mes droits en tant que sujet de données ?

Vous pouvez contacter Alltech si vous souhaitez accéder à vos données personnelles ou si vous souhaitez que vos informations soient corrigées ou supprimées. Vous pouvez également déposer une plainte auprès de l'équipe Alltech Data Privacy ou poser toute autre question relative aux données. Veuillez les contacter à privacy@alltech.com.

Notification de politique de cookie (séparée) - Pop up sur le site Web lorsque l'utilisateur accède au site

Comment comprendre et utiliser les cookies sur ce site ?

Un cookie est un petit fichier composé de lettres et de chiffres stockés (avec votre consentement) sur votre navigateur ou sur le disque dur de votre ordinateur. Les cookies contiennent des informations qui sont transférées sur le disque dur de votre ordinateur. Les cookies nous permettent de vous identifier (ou plus exactement de votre ordinateur) lorsque vous visitez notre site Web.

Lorsque vous visitez notre site Web, notre serveur enregistre automatiquement certaines informations relatives à votre visite, telles que votre adresse IP, le type et la version du navigateur, le réglage du fuseau horaire, le flux de clics complet des URL (Uniform Resource Locators) vers, via et depuis notre site; les temps de réponse des pages, les erreurs de téléchargement, la durée des visites sur certaines pages, les informations d’interaction entre elles (telles que le défilement, les clics et les survols), ainsi que l’heure et la durée de votre visite.

Les cookies et la technologie de suivi sont utiles pour collecter des informations telles que le type de navigateur et le système d’exploitation, suivre le nombre de visiteurs sur le site et comprendre comment les visiteurs utilisent le site. Les cookies peuvent également aider à personnaliser le site pour les visiteurs. Les données personnelles ne peuvent pas être collectées via des cookies ou d'autres technologies de suivi ; cependant, si vous avez déjà des informations personnelles identifiables sont fournies, les cookies peuvent être liés à ces informations.

Détails sur les cookies, nous pouvons être trouvés ICI.

We are dedicated to working alongside producers in order to optimize the well-being and performance of animals, unleashing their true genetic potential through nutrition.