David Collier and his team run a busy beef finishing and tillage farm in Kilbride, Co. Carlow. He finishes over 600 beef cattle every year and the vast majority of his feed is grown on his own farm.

“Pulp nuts and hipro soya are the only feedstuff I buy in,” says David. “Otherwise, we incorporate home-grown barley, wheat, oat, beans, maize, straw and silage into our ration. Every day, 6.2 tonne of beet is chopped and mixed into the total mixed ration (TMR). This way, we don’t need a separate beet chopper.”

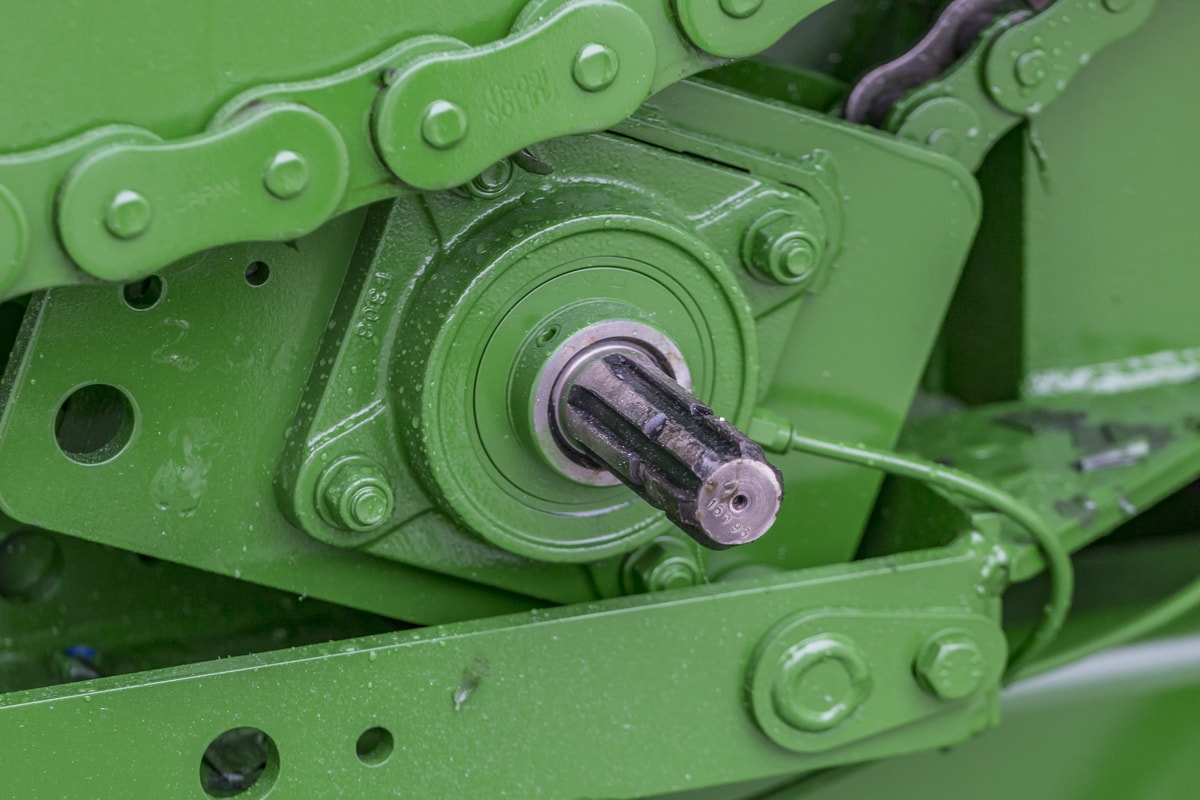

David was a long-time owner of a 14 m³ KEENAN Klassik. But, after 12 years of service, he traded it in against a bigger, 17 m³ KEENAN Approved MechFiber350 used paddle mixer.

“The KEENAN reliability is something I don’t want to miss,” explains David. “We use the machine 365 days a year, this is why I went for a KEENAN machine.”

The MechFiber350, with a high feed-out, has everything that David was looking for — a Hardox-hardened steel liner to prolong the life of the mixing chamber and a bale handler to incorporate bales into his ration.

“Straw and silage bales are quickly dissolved in the bale handler and incorporated into the TMR,” David remarks. “The mix quality with the new machine turns out to be better because of the bigger capacity.”

As an additional feature, David added reflective strips onto the machine and supporting beams in his shed. A light connected to the machine illuminates the reflective materials and makes manoeuvring the machine in tight feed passages easier.

David’s experience attests to the longevity and quality of KEENAN diet feeders. He was able to find the perfect machine for his farm requirements with a KEENAN Approved used machine.