Aquaculture feed for a sustainable future

As aquaculture continues to grow in a more sophisticated culture system, we need to adapt the feed for aquatic animals like fish and shrimp. Speaking at the Alltech ONE Ideas Conference in June 2021, Ben Lamberigts, manager of quality, research and nutrition at Alltech Coppens, offered his insight on nutrition for a sustainable future through the four pillars of fish nutrition concept.

The current state of aquaculture feed production

A rapidly growing aquaculture industry has led to increasing demand for good quality aquaculture feed. Yet, the availability of fishmeal is limited. Even if we reduce 50% of the world’s fishmeal inclusion, we still need almost 1.5 million metric tons of fishmeal by 2050, which is simply not available.

“It’s a challenge that we have to solve before we can grow the aquaculture industry,” said Lamberigts. “But the industry is working on this, and we are doing a very good job.”

In fact, we have already lowered the fish in fish out (FIFO) factor since the ‘90s. Still, we need more fishmeal alternatives, such as:

- Animal byproducts (hemoglobin, blood meal, poultry meal)

- Vegetable protein sources (sunflower meal, wheat protein, soybean meal)

- Insect meals (mealworm, black soldier fly meal)

- Byproducts from human consumption (fish byproducts or salmon)

.png)

While the global aquaculture production has achieved a 0.27 FIFO rate, Alltech Coppens even lowered the FIFO factor to 0.10, which means only 100 grams of wild-caught fish is needed to produce 1 kilogram of farmed fish.

How did Alltech Coppens do this?

Understanding what fish really need

“First, we need to understand the basics of nutrition,” noted Lamberigts. “No fish has a requirement for fishmeal or even a requirement for a specific raw material.”

What fish require are:

- Essential nutrients, such as digestible protein, fat for energy, vitamins and minerals

- Palatable compound feed, so the fish eat the feed

- Good water quality in aquaculture, because fish swim, defecate and eat in the same environment

“If we define the alternatives with these requirements, those alternatives are not alternatives anymore,” Lamberigts continued. “We split them up into single metrics, so we can compare them better between each other and to the fishmeal.”

This has been done in human food items. An example is the nutrition score on food packaging. Nutritional scoring, as well as sustainability scoring, helps consumers compare between products. Through labeling and pictograms, the producers now make it possible for them to make the right decision.

That is what Alltech Coppens has been doing for the alternatives to fishmeal by dividing them using different metrics that are categorized into four pillars: Palatability, Performance, Pollution and Planet.

The four pillars of fish nutrition for a sustainable future

1. Palatability: The feed needs to be palatable for the fish

“(Palatability) is the most important pillar because if the food is not eaten by the fish, there is no performance and pollution control is very bad,” Lamberigts explained.

The graph below shows a trial with rainbow trout at the maximum feeding level. The y axis represents the feed intake in gram/kilogram metabolic rate, and the x axis shows the taste.

There were two different treatments:

- Blue line: 100% of the protein came from fishmeal (fishmeal-based diet)

- Green line: 100% of the protein came from vegetable sources (vegetable diet)

The diets for these two groups were switched on day four. Interestingly, there was a drop in feeding levels for both diets. That means that even the fish that received a vegetable diet before day four, that switched over to what was assumed to be a more palatable diet (the fishmeal diet), also had a drop in feeding level; nevertheless, that drop in feeding level recovered much quicker than the other group.

From this trial, two crucial metrics regarding palatability were identified:

- The drop in feeding level after the diet switch

- The recovery period needed from the change

“If we quantify this effect for all the alternatives, we can calculate and make the best combination between the alternatives to get the same performance as what we had with the fishmeal,” noted Lamberigts.

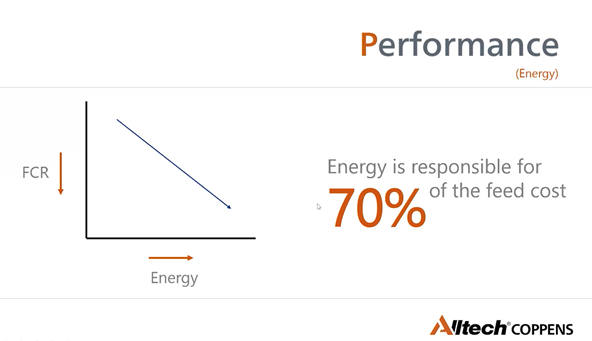

2. Performance: The fish has a need for essential nutrients

Energy is the driver of growth. When the energy level increases, the feed conversion ratio (FCR) decreases and the growth performance of the animal rises.

Furthermore, energy is responsible for 70% of feed cost.

“So, if we increase the energy level of a certain feed by 10%, we also increase the price of that feed by 70%,” said Lamberigts.

But what is energy?

The gross energy is the energy that is available in that feed ingredient. If the animal can digest that energy, it becomes digestible energy. If the digestible energy is correctly transferred into the animal’s body or maintenance, it becomes net energy.

Comparing the net energy of different types of feed, as well as considering palatability and sustainability, can help producers choose the best feed for performance.

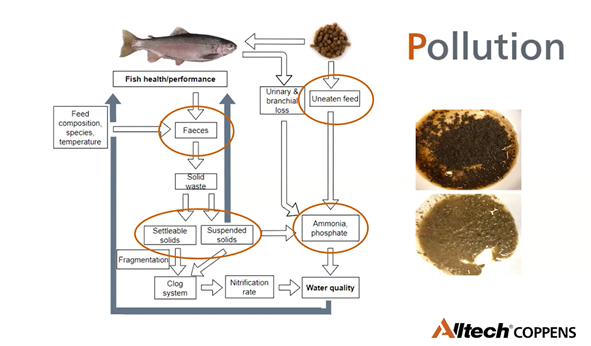

3. Pollution: The fish requires good water quality

Three main factors that affect water quality are:

- Uneaten feed

- Ammonia and phosphorus excretion

- Feces (how fast they sink, what part is settleable and what part is suspended)

An example of pollution control is fat digestibility, which depends a lot on the water temperature. Pollution in terms of fat is becoming a big problem in trout farms with a low water temperature (below 8° Celsius), especially if the feeding level is high.

A fatty acid with a low melting point, like linseed or soy oil, has high fat digestibility. In that case, even if the water temperature goes down, the effect is low.

Alltech Coppens knows the fatty acid composition of their different alternatives to fishmeal and fish oil. Consequently, they can use this model to predict fat digestibility and prevent fat from polluting the water.

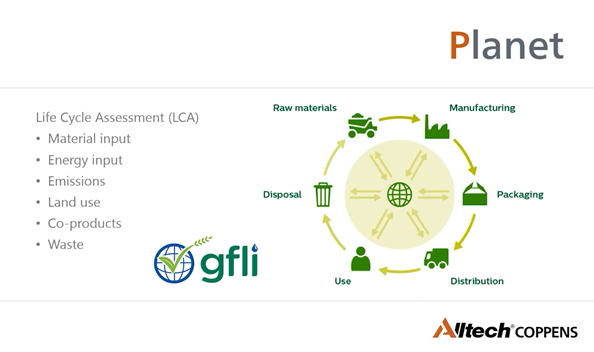

4. Planet: The environmental sustainability of the feed

“Being sustainable and assuring that we can grow this industry further, it is becoming a necessity that we quantify the effect of our products, of our raw materials, of our fishmeal alternatives on the environmental impact,” said Lamberigts.

Alltech Coppens has been doing this via the Life Cycle Assessment (LCA). It is not only looking into the carbon footprint of a single ingredient but also the different parts of how a product is produced, used, distributed and how the waste is treated.

Combining all these effects gives Alltech Coppens a total sustainability score of the different raw materials, which helps their customers to choose the right sustainable feed.

“If we quantify and measure all these pillars and put them in a software system, we can make the best combination of our alternative protein sources in combination with the fishmeal at the lowest price for the best quality,” noted Lamberigts.

Concluding the presentation, Lamberigts hoped he showed the audience that alternatives to fishmeal are not alternatives; they are ingredients.

“Insect meal, soy protein, poultry meal; if we are able to quantify the metrics behind these ingredients, we are also able to use them in the proper way,” Lamberigts advised. “When it comes to sustainability, pollution control, performance, palatability, we are now able to use these different alternatives and these different fishmeals in the correct way to ensure the growth of our aquafeed industry.”

Visit one.alltech.com for more information.